BY JENNY CALLISON, POSTED JUN 17, 2022

New short-term programs at Cape Fear Community College aim to equip local residents with the basic skills and knowledge to fill some of the many manufacturing vacancies in New Hanover and surrounding counties.

This month, the college launched manufacturing production technician, machining applications and distribution warehousing courses to enable individuals to qualify for entry-level positions with the nearly 100 manufacturers in the lower Cape Fear area.

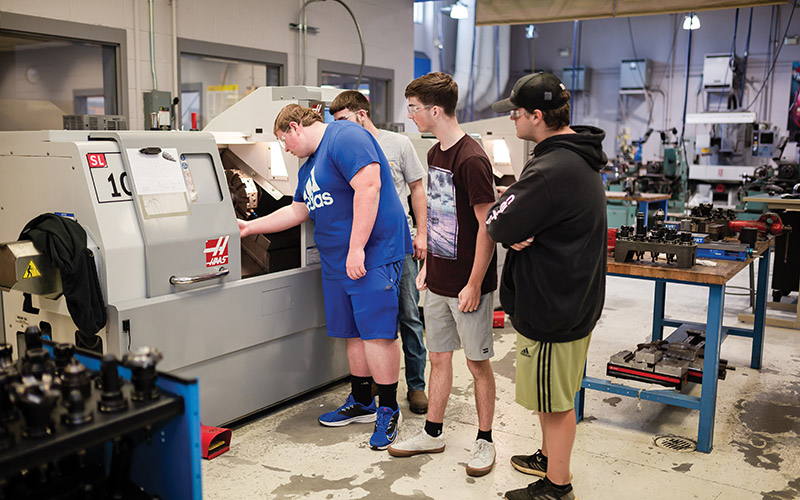

“What they are starting out with is the basics,” said Eddie Sholar, director of CFCC’s computer integrated machining program. “The first thing is safety. We don’t want anybody to get hurt; that could be a career-ending incident. Other things we’re teaching them form the foundation of being able to go into a manufacturing or machining [plant] and get a job.”

North Carolina, like many other states, faces a severe shortage of manufacturing workers as companies bring their operations back to the United States. The N.C. Department of Commerce estimates that the state will need nearly 500,000 more manufacturing workers by 2028 – almost 7,500 in the Wilmington area alone.

Both Brunswick Community College and CFCC are working to address this need with the recently formed Manufacturing Partnership, a group of nearly 40 local companies.

“We started [the Manufacturing Partnership] last year to help shape the perception of a manufacturing career and to help shape the curriculum in high schools and community colleges,” said Michael McWhorter, CEO of Burgaw- based Mojotone, a manufacturer and repairer of guitar amps and related products. “Cape Fear [Community College] came to us and said ‘What kind of skills are you looking for?’ One aspect is OSHA safety training. There’s also hand tools operation and measurements. I really applaud Cape Fear for coming to the source. They really listened to us when they put [these courses] together.”

The three short courses, which acquaint students with fundamentals they should know before venturing into the workplace, aren’t to be confused with Cape Fear’s two-year technical programs, such as its associate’s degree program in computer integrated machining. They are designed to get an aspiring employee hired and ready for further on-the-job training for a specific job, from running a simple machine to operating a forklift.

Traditionally, community colleges have tended to create programs and then try to sell them to the business community, said Jim Flock, general manager of Blair-HSM, a Leland-based maker of aircraft landing gear.

“We’ve reversed that dynamic,” he said. “We’re dictating the terms of what we need. Now they’re getting input from us. Everyone I have dealt with at Cape Fear and Brunswick Community College has gone above and beyond.”

“We brought together more than 35 manufacturers to form the Cape Fear Manufacturing Partnership,” said CFCC’s workforce training coordinator Erin Easton, who helped develop the partnership. “One of their biggest challenges is attracting and training job seekers so they can continue to grow their business in this region. [The manufacturers] create their own agenda; we are there to support them and provide resources. I’m one of the convenors, and there are three other entities involved: the Cape Fear Workforce Development Board, Wilmington Business Development and Brunswick Business & Industry Development (BID).

Providing an employer-driven launching pad to get individuals into manufacturing is “economic development, pure and simple,” said John Downing, CFCC vice president for economic and workforce development. “They say that for every dollar you spend on manufacturing, you’ll get a dollar and some change back from the local economy.”

The short-term courses aren’t just for recent high school graduates, said Cheryl Morlote, senior manager of people and culture at Wilmington-based Yogasleep, which manufactures sound machines. They are for anyone looking for a new opportunity.

“Most of these jobs are full-time, with benefits,” she said. “You’re not necessarily going to find that at other places. When comparing a career in manufacturing with other jobs, you have to look at the whole package: health care, short-term disability.”

Like the other manufacturers interviewed, Morlote wants to change the public perception of a job in manufacturing as low-level, dirty work.

“Our manufacturing floor is heated, air conditioned and fairly clean. Sound machines have to be clean. People can stand or sit,” she said. “Just like in any business, you develop relationships with your coworkers. We have music playing on the floor; we found it makes a big difference in helping our workers concentrate. You have to be cognizant of what people’s wants and needs are to retain people who want to do the work. You have to listen to them.”

Sholar echoed Morlote’s message about the work environment.

“In general, manufacturing is no longer dangerous and dirty,” he said. “You can wear a light-colored shirt when you go in to work and it’s still the same color when you come out. You’re not swimming in grease.”

The jobs Manufacturing Partnership members are offering are high-paying, Flock said. “We need to change that perception and open people’s eyes to what we’re doing here, so we can fulfill our staffing needs.”

FIRST STEPS

Flock said Blair-HSM is on a team with Boeing, Sikorski, Lockheed and Honeywell that is one of two finalists for a major “transformational” contract to build the U.S. Army’s new Future Long-Range Assault Aircraft (FLRAA). The contract will be awarded later this year. If this team wins the contract, said Flock, Blair-HSM will need to hire 50 or more additional workers.

Barber sees the short courses as vital to not only making more people interested in a career in manufacturing, but also in helping them thrive on the job.

“We have various operations within our facility, from machine operators that operate laser-cutting machines to welders, to assemblers and press brake operators,” Barber said. “For each of those positions you have to have a basic understanding to be successful and be safe. You figure a grill is a couple hundred pounds. You have to have a forklift to move everything around, and you have to have a basic understanding of proper lifting techniques so you don’t strain your back. Basic OSHA safety awareness is critical.”

The partnership members know the new short courses aren’t a quick fix to a shortage of prepared workers, but they are an important first step to expanding the workforce and putting a spotlight back on careers in manufacturing as a path to a stable financial future with opportunities for advancement.

The outsourcing of manufacturing operations to other countries has had serious economic repercussions, Flock said.

“It’s created a service economy with highly paid professionals and low-paid workers,” he said. “We need to bring manufacturing back, to create a stable middle class and to solve some supply chain problems.”

Key to beefing up the manufacturing workforce, Morlote said, is getting the message out to young people that a career in manufacturing is an attractive path to prosperity.

“We’ve talked about this in the partnership,” she said. “We really need to start in high school, even middle school. It comes down to people, kids especially, knowing there are other opportunities besides going to college or working in the hospitality industry.”

https://www.wilmingtonbiz.com/more_news/2022/06/17/retooling_a_workforce/23324